News

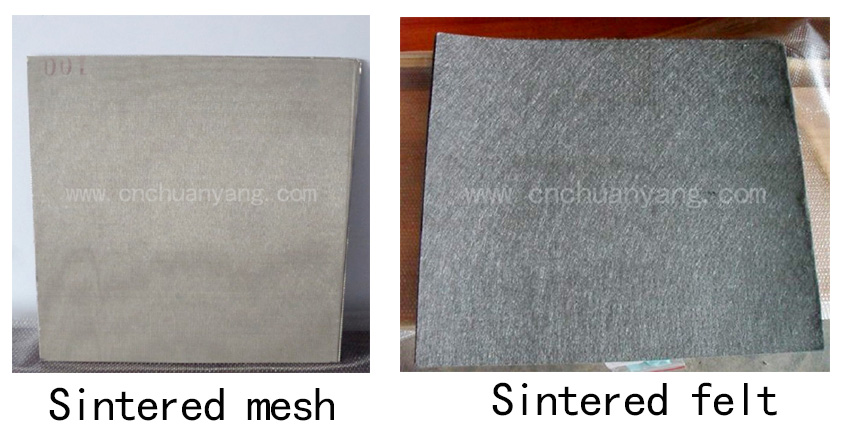

Compared and analyzed for Sintered mesh and Sintered felt

2017-07-31

| Product | Sintered mesh | Sintered felt |

| Material | Stainless steel wire mesh | Stainless steel fiber |

| Process | Made of Multi-layer stainless steel wire mesh superposition, sintered, pressurized, rolling. | Made of stainless steel fiber laying, superposition, sintered. |

| Characteristics | High-temperature corrosion resistance, high mechanical strength, high filtration precision | High-temperature corrosion resistance, High dirt-holding capacity, high filtration precision |

| Application | Hot gas liquid filtration and cooling, powder conveying, pharmaceutical | Petroleum chemical, polymer, oil refining process filtration, high temperature dust removal, catalyst carrier, hydraulic fuel filtration |

Same point:

1. Material: Stainless steel (304,316 and 316L)

2. Sintering process

3. High-temperature corrosion resistance

Difference:

Sintered mesh: made of stainless steel wire mesh, better high mechanical strength and filtrating precision (1-200 micron)

Sintered felt: made of stainless steel fiber, high dirt-holding capacity and filtration precision (5-60 micron)

Application:

Sintered mesh: used in hot gas liquid powder filtration and conveying

Sintered felt: used in polymer melt (oil and plastic) filtration and high temperature dust removal

Xinxiang Chuanyang Machinery Co.,LTD has always been committed to providing customers with high quality filters and filter elements, widely used in metallurgy, petrochemical, fine chemical, chemical fiber, water treatment, pharmaceutical, electrical and mechanical industries, welcome to contact us.